Overall Goal

The goal of this portion of the project was to create frac sand mining suitability and environmental/cultural risk models for Tremeapleau County using geoprocessing tools and model builder. Each model accounts for several important factors, and when joined together, the two models can be used to create a single model for determination of ideal mining locations.

Suitability Model

Objectives

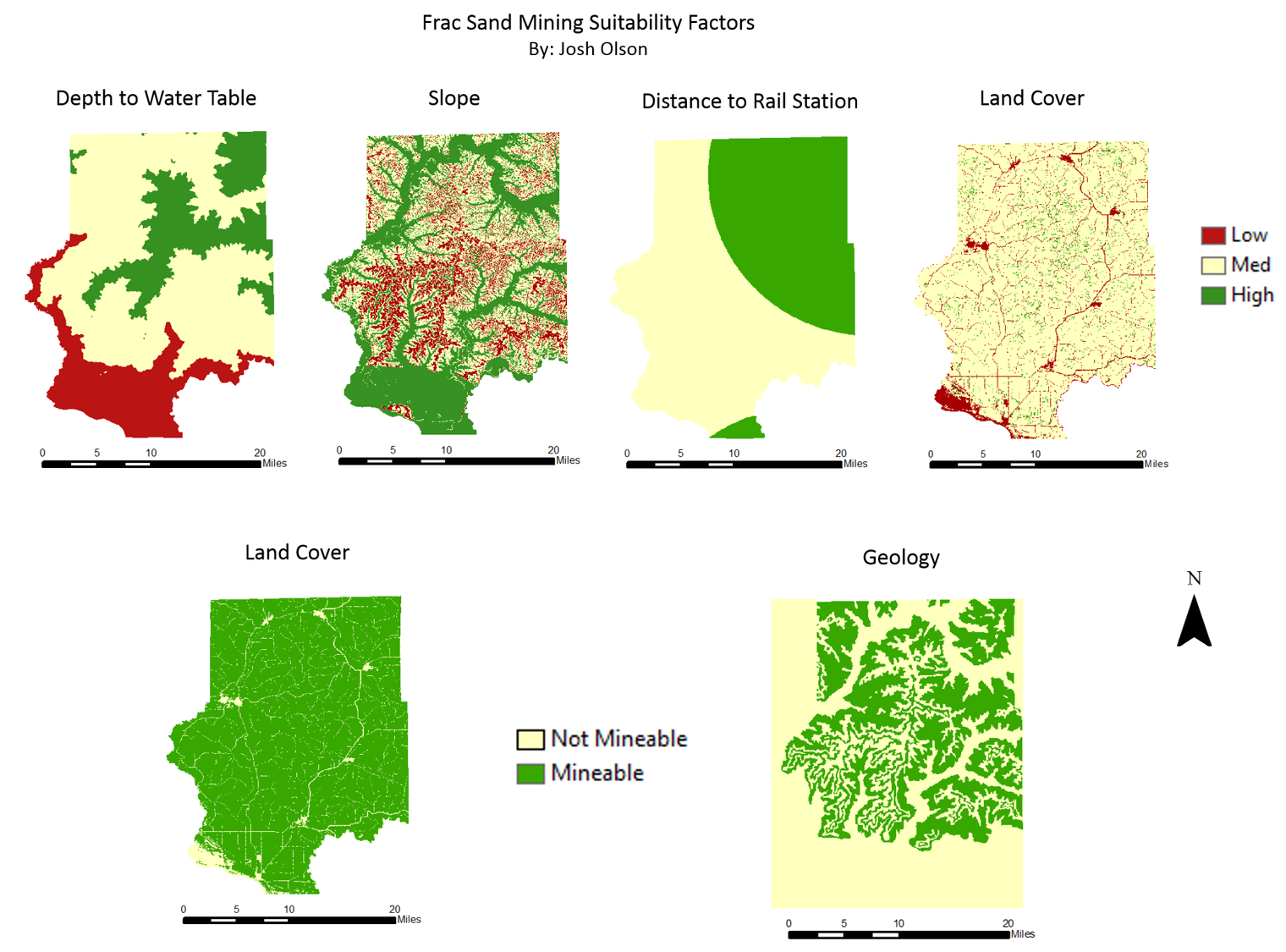

The objective of the sustainability model was to create layers that account for/rank geology, land cover, distance to the nearest railroad station, slope, and water table depth according to their effect on the suitability of a region for frac sand mining. The rankings associated with each layer were combined, creating a single, comprehensive suitability index model. Additionally, any area with land use unsuitable for mining was removed from the ranking.

Data Sources

Data came from a variety of sources, which included past project work, as well as publicly accessible data sets. County/state and bedrock geology data were provided by the professor. Land cover data was downloaded from the NLCD website, rail loading points were generated, and an elevation raster was created in class for exercise 4. Water-table information was downloaded from the Wisconsin Geological Survey.

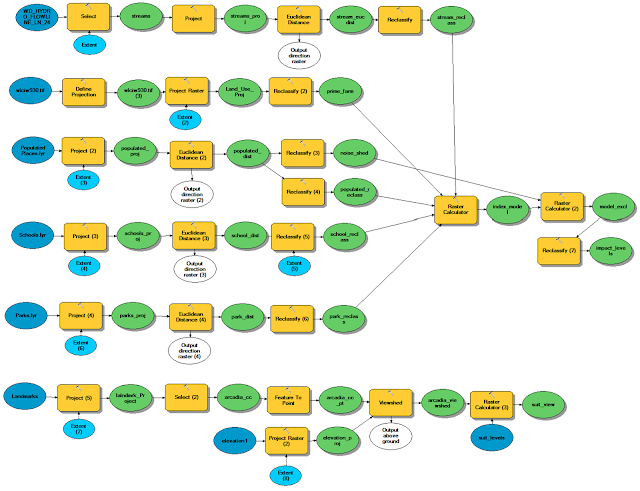

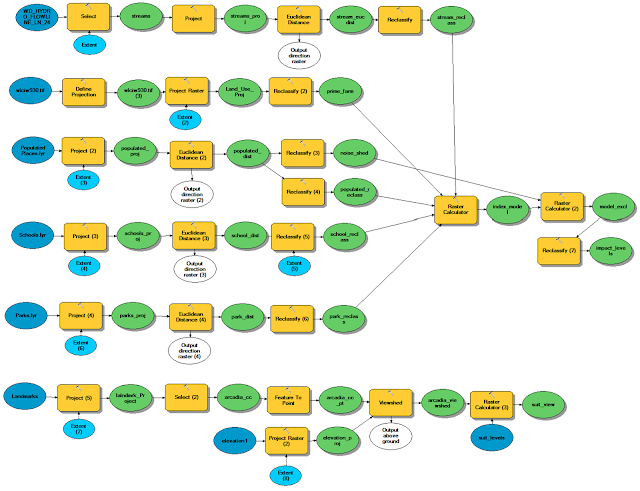

Methods

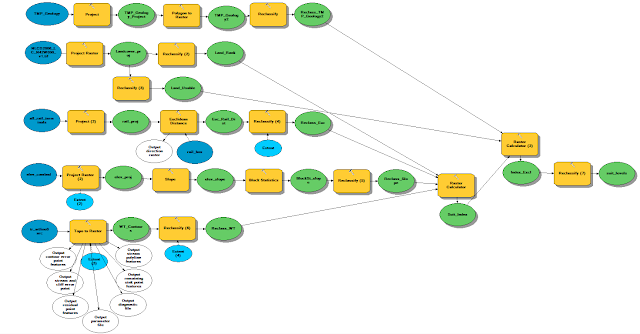

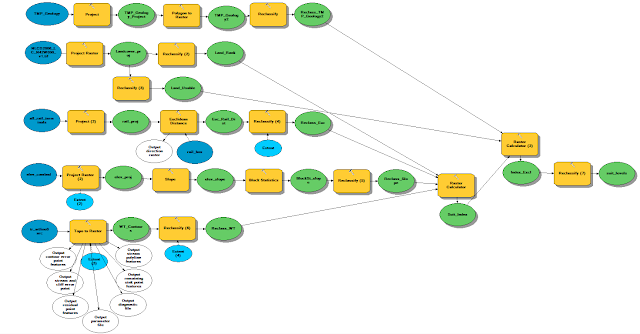

The first step for each layer was ensuring they were in the correct projection (Fig. 6). I used the county projection system specific to Trempealeau (NAD_1983_HARN_WISCRS_Trempealeau_County_Meters)

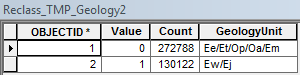

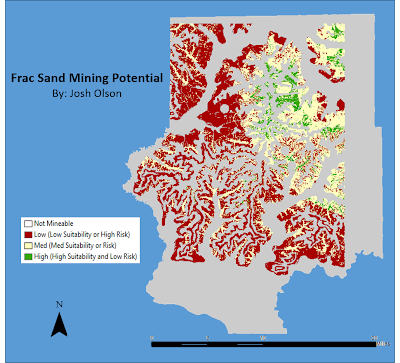

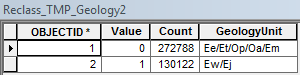

. For the geology layer, I had to convert the initial polygon features to a raster and reclassified the values. Because the Jordan and Wonewoc are the only formations suitable for frac sand production, they were given a value of 1. All other formations were given a value of 0, indicating no potential for frac sand mining (Fig. 1).

|

| Figure 1. The Wonewoc and Jordan formations (Ew/Ej) were reclassified as the only geologic units desirable for frac sand mining. |

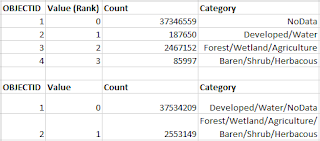

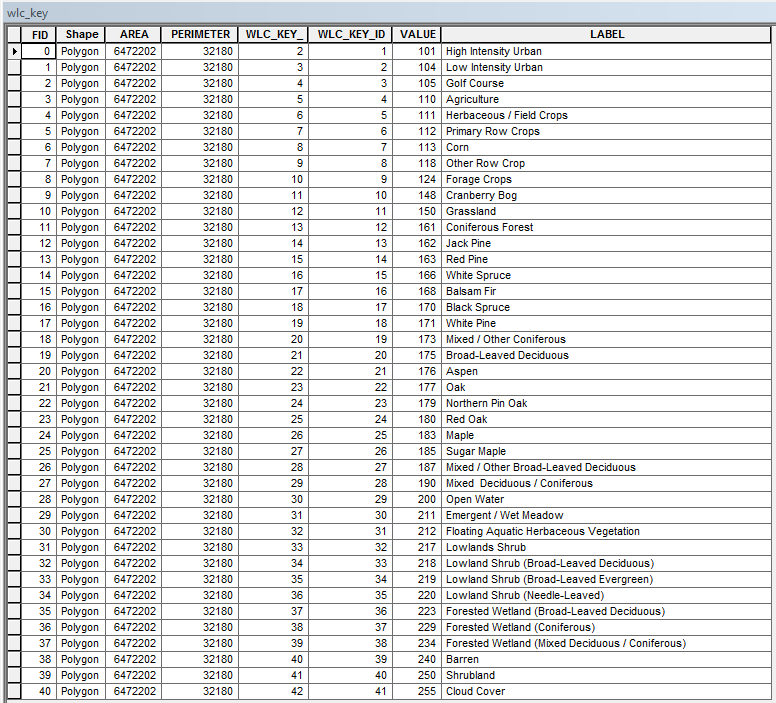

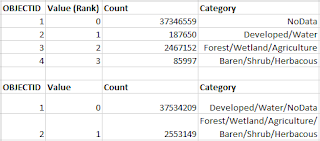

The land cover data required two separate reclassifications (Fig. 2). One reclassification generated a raster with three separate rankings. Developed areas and open water were given a value of 1 (low suitability). Forested areas, wetlands, and cultivated/agricultural land were given a value of 2 as they could be mined, but would require some additional effort intially. Baren, shrubland, and herbacous areas were given a value of 3 (high suitability) because they could be cleared and ready for mining with minimal effort. The second reclassification was used to create a raster that separated out developed and water filled areas, as they are essentially unmineable.

|

| Figure 2. The top table was used to rank land cover based on suitability for mining. The bottom table was created to allow for the removal of developed and water filled areas from the model. |

Euclidean distance was used with the rail terminal data to determine how far each cell in the Trempealeau County raster was from the nearest rail loading point. The raster was then reclassified to create three rankings (Fig. 3). Because the perceived inconvenience of truck transport is related to the availability of alternative options, I used Jenks' natural breaks and gave cells farthest from rail access a value of 1 and those closest a value of 3.

|

| Figure 3. Reclassification of euclidean distance data (in meters) for rail loading points. |

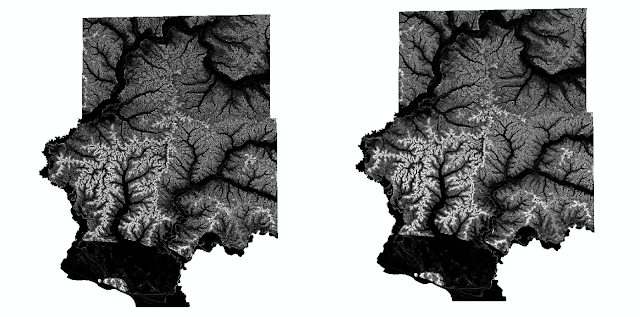

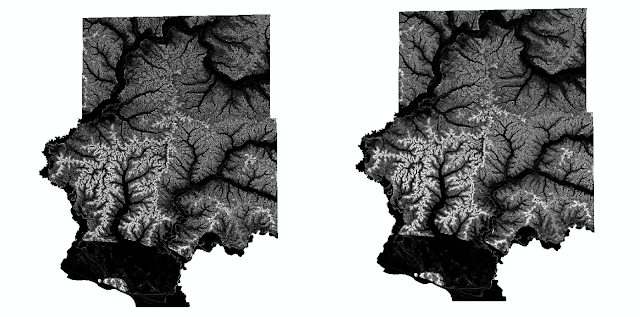

Elevation data from exercise 4 was run through the slope tool to determine flatter, more convenient mine options. Block statistics were used with a 3 cell by 3 cell rectangle that calculated the mean to smooth out the data and eliminate any "salt and pepper" effect (Fig. 4). Steep slopes were given a value of 1 (least suitable) and flat areas were given a value of 3 (most suitable).

|

| Figure 4. The original slope raster (left) and the smoother slope raster generated using block statistics (right). |

Depth to water level data had to be imported as a coverage. Topographic data was then converted to a raster based on the elevation of the water table. Because the frac sand mining process requires significant water supplies, shallow water table elevations were assigned a value of 3 (most suitable) and deep water table elevations were assigned a value of 1 (least suitable) (Fig. 5).

|

| Figure 5. Water table elevations (old values) were used to classify the suitability of areas for frac sand mining based on the availability of water. |

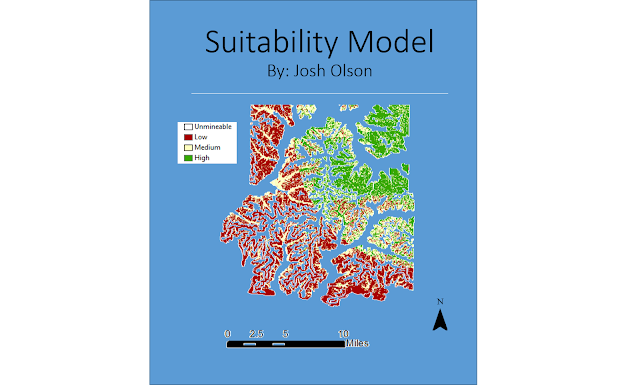

Raster calculator was used to add the values for the land cover, rail distance, slope, and water table depth rankings ("%Reclass_WT%" + "%Reclass_Slope%" + "%Reclass_Euc%" + "%Land_Rank%"). The sum was then multiplied by the geology and usable land rasters to eliminate areas where mining wasn't feasible ("%Suit_Index%" * "%Land_Usable%" * "%Reclass_TMP_Geology2%"). Finally, the values were reclassified using Jenks' natural breaks to determine areas of high, medium, and low suitability (Fig. 13)

|

| Figure 6. A model for determining frac sand mining suitability based on geology, land cover, rail distance, slope, and water table depth. |

Environmental/Cultural Impact Model

Objectives

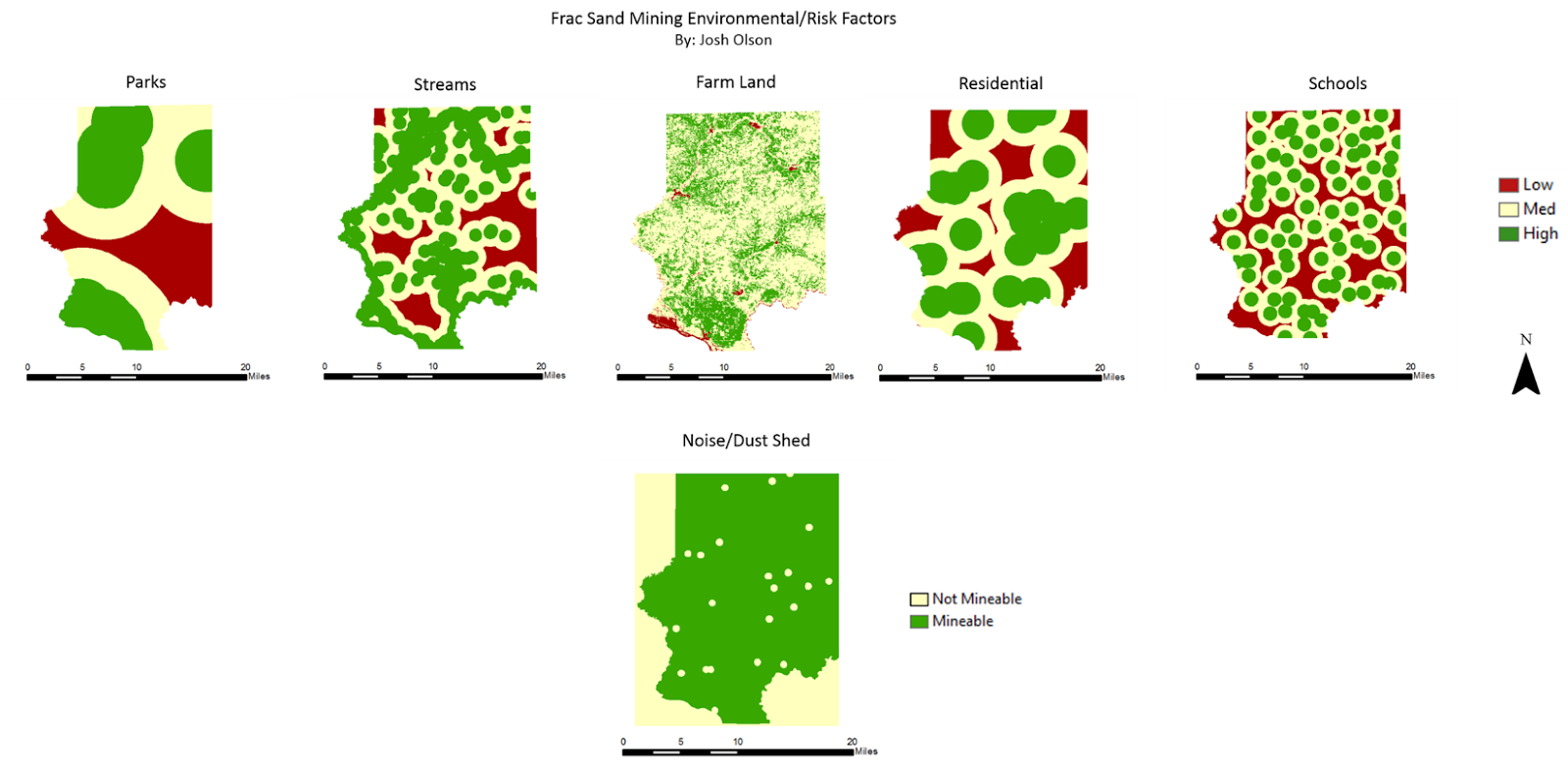

The objective of the sustainability model was to create layers that look at the effect on streams, agriculture, residential areas, schools, and parks based on proximity to mining locations. The values from each layer were divided into three categories 1 (low impact), 2 (med impact), and 3 (high impact). The rankings for all the layers were combined, creating a single, comprehensive risk model. Additionally, any area within 640 meters of residential locations (noise/dust shed) was removed from the model.

Data Sources

Data for this portion of the project came from two different sources. Stream and land use data was downloaded from the DNR website. Residential, school, and park locations were provided by ESRI. Populated places (ESRI) was used for residential data. This data is beneficial in that it focuses on main population centers. However, it does not adequately account for rural homes that tend to be more isolated.

Methods

As in building the suitability model, the first step for each layer was ensuring they were in the correct projection (Fig. 10). To stay consistent, I again used the county projection system specific to Trempealeau (NAD_1983_HARN_WISCRS_Trempealeau_County_Meters)

. For the stream data, I removed the overland flow categories, as overland flow is considered runoff rather than stream flow in the hydrogeologic community. Beyond that, the processing of most layers stayed similar. Euclidean distance was used to generate four rasters showing the distance from each cell to streams, populated/residential areas, schools, and parks. Possible mine locations close to features were assigned values of 3 (high impact) while those further separated were given value of 1 (low impact) using the reclassify tool.

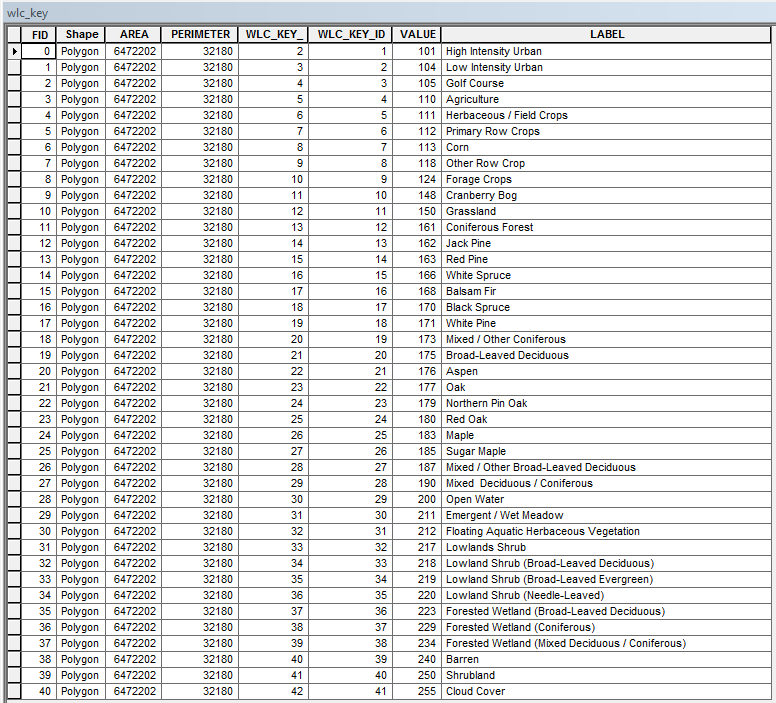

Land cover data was evaluated differently because the concern is for farming potential of potential mine locations rather than proximity (Fig. 7). Croplands or areas that are already being used for agriculture were given a value of 3 (high impact). Forested and vegetated areas that had the potential to be turned into farm land, which were the majority, were given a value of 2 (med impact). Developed areas and those with open water were given a value of 1 (low impact) as they are very unlikely to be used for agricultural purposes.

|

| Figure 7. Land cover data was reclassified based on farming potential (LABEL). |

An additional reclassification of proximity to populated areas was run to create a dust/noise shed buffer (Fig. 8). Areas within 640 meters of residential locations were given a value of 0, and areas outside the buffer were given a value of 1.

|

| Figure 8. 640 meter buffer areas (white, circular holes) were removed from the model around populated locations. |

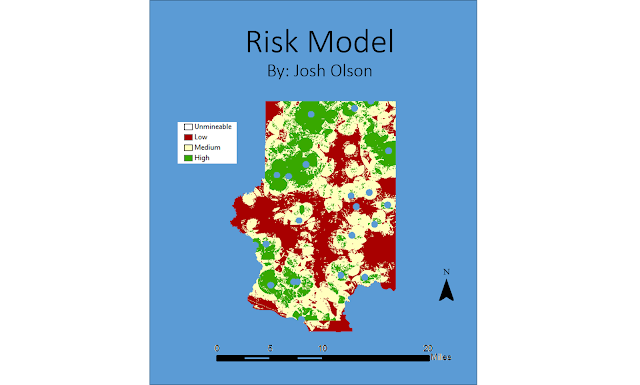

The rankings of stream, school, residential, and park proximity, as well as farm potential (prime_farm), were summed using raster calculator to generate a risk index ("%park_reclass%" + "%school_reclass%" + "%populated_reclass%" + "%prime_farm%" + "%stream_reclass%"). These values were then multiplied by the dust/noise shed buffer ("%index_model%" * "%noise_shed%") to eliminate any areas within the unmineable zone. Finally, the raster was reclassified using Jenks' natural breaks to produce three overall impact rankings (high, med, low) (Fig. 15).

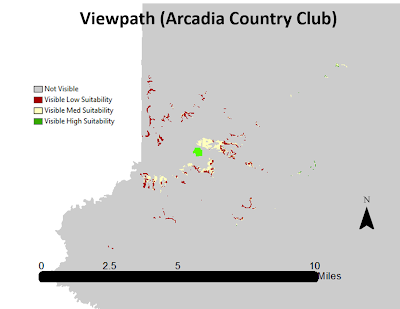

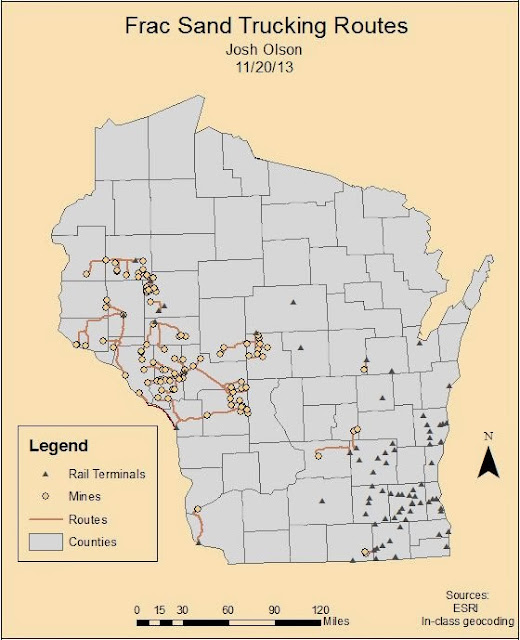

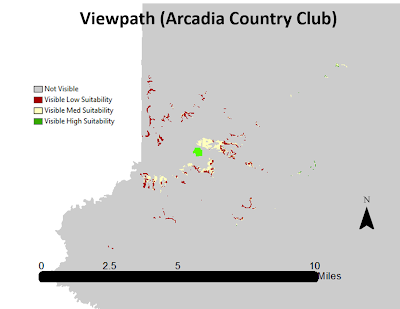

As a side project, the viewpath tool was run to determine if any mining locations would be visible from the Arcadia Country Club (Fig. 9). Clearly, visibility extends miles beyond the actual site. This likely indicates a frac sand facility in this area would alter the scenery, even from significant distances.

|

| Figure 9. Visibility clearly extends several miles away from Arcadia Country Club (lime green) in all directions. |

|

| Figure 10. A model for determining the environmental/cultural risks associated with frac sand mining locations. |

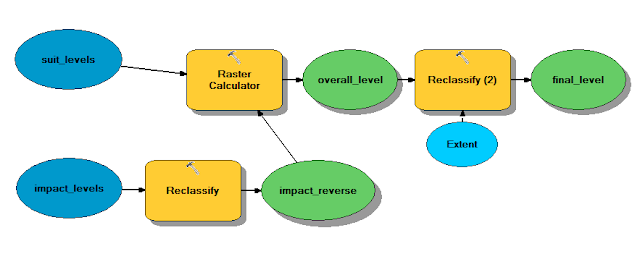

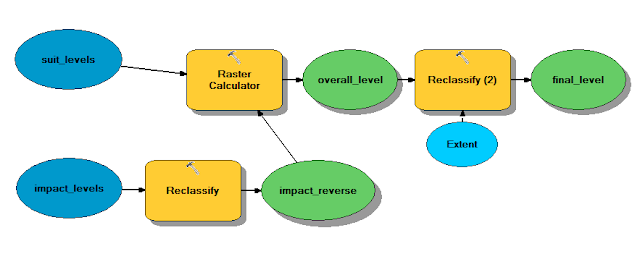

Overlay (Combined) Model

Objectives

The objective of the overlay model was to combine both the suitability and risk models to determine ideal locations for frac sand mining that pose minimal environmental/cultural risk.

Data Sources

Data came from the suitability and risk models, which were based on the various sources described earlier.

Methods

As all data was in the correct projection, no additional projection was necessary (Fig. 11). In order to find areas with high suitability and low risk, the risk model was reclassified so that low risk areas were assigned higher values and high risk areas lower values (flipped from original). The values of the two models were then multiplied together to determine potential for mining. The highest potential areas had a value of 9, and the lowest potential areas had a value of 1. The combined values were then reclassified into three categories (high potential, medium potential, low potential) using Jenks' natural breaks (Fig. 16).

|

| Figure 11. The final combining of both the suitability and risk model into a single model for determining ideal frac sand mining locations. |

Results

|

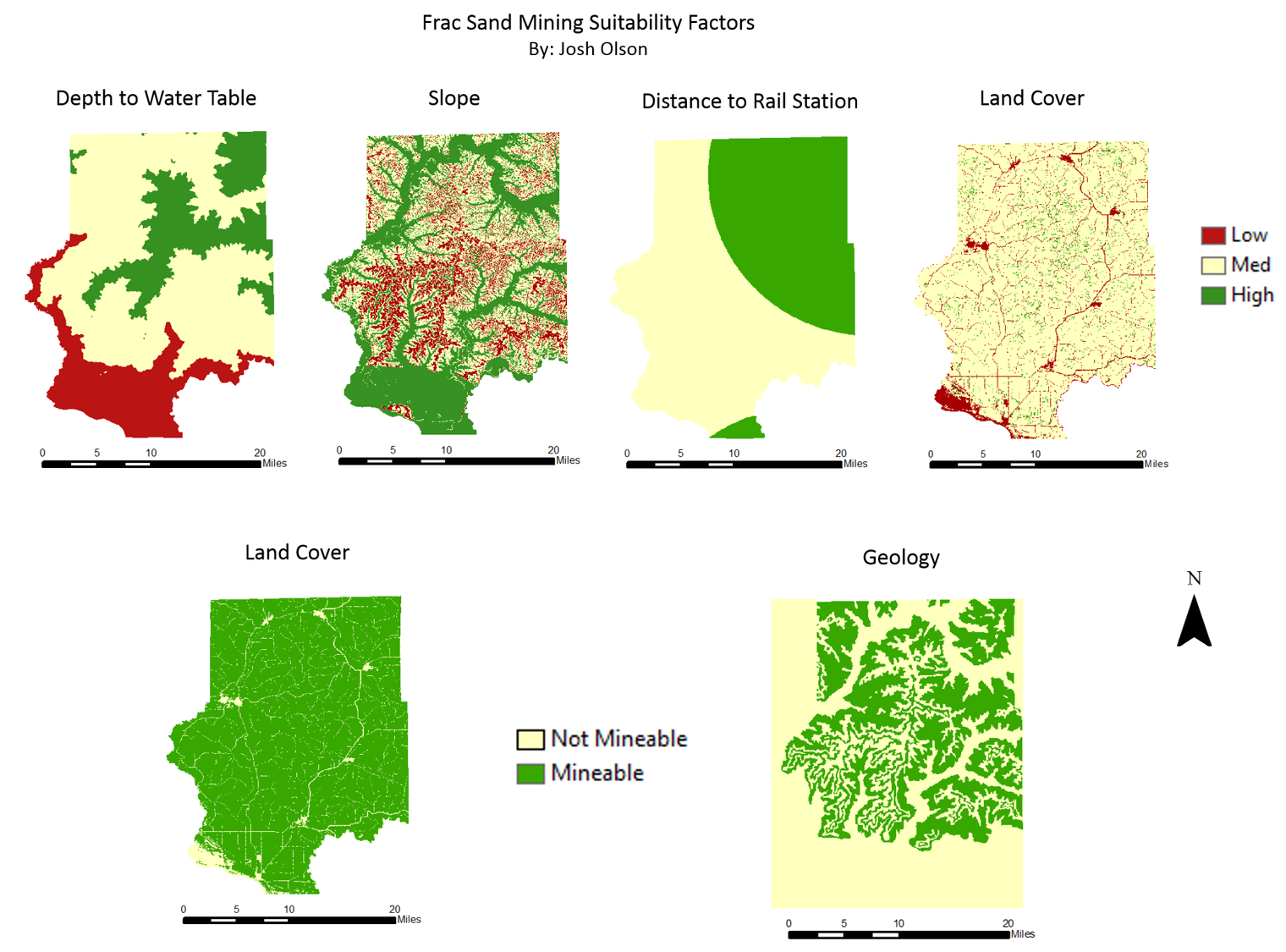

| Figure 12. Maps of suitability factors ranked high-low suitability (top) or mineable/not mineable (bottom). |

|

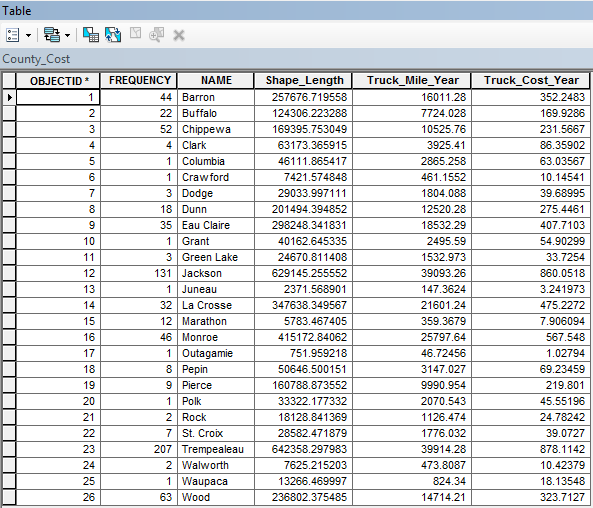

The various factors that account for mine suitability vary greatly in the areas they recommend for mining (Fig. 12). Based on geology and land cover, much of the county is mineable. There appears to be a possible trend of higher suitability in the northeast and lower suitability in the southwest when looking at the water table, rail station, and land cover data.

|

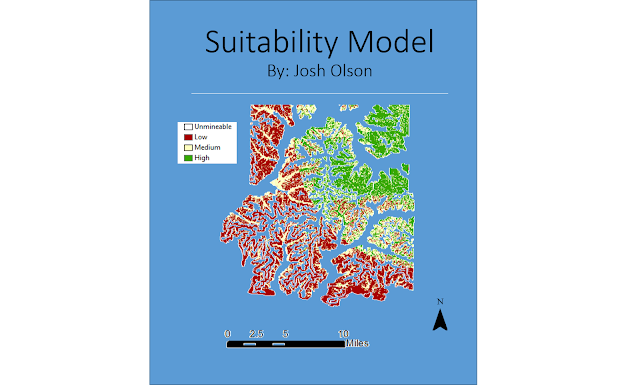

| Figure 13. Suitability model created by summing the various suitability factors. |

When all of the factors are combined, the trend that was only somewhat visible initially becomes more apparent (Fig. 13). The northeast corner of the county is clearly the best suited for frac sand mining. It is interesting how the shape of the distance to rail data was preserved in the northeast, while the small circle fragment in the south is essentially gone. This likely indicates that, not only does distance to rail play a significant role in suitability, but other factors are contributing as well.

|

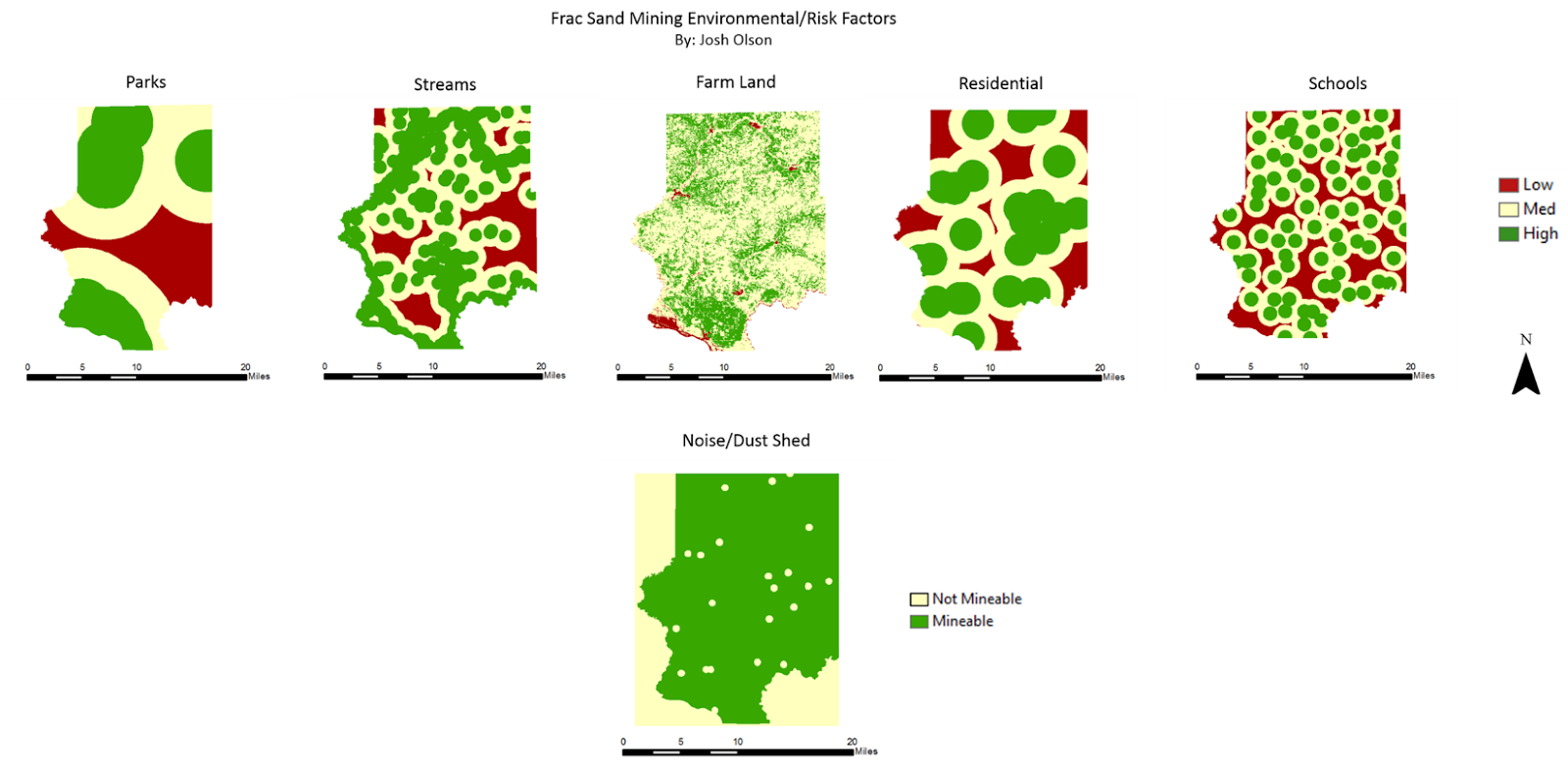

| Figure 14. Maps of risk factors ranked high-low risk (top) and mineable/not mineable (bottom). |

Similar to the suitability factors, the risk factors do not immediately indicate a preferred region for mining. Different factors show lower risks in differing areas (Fig. 14).

|

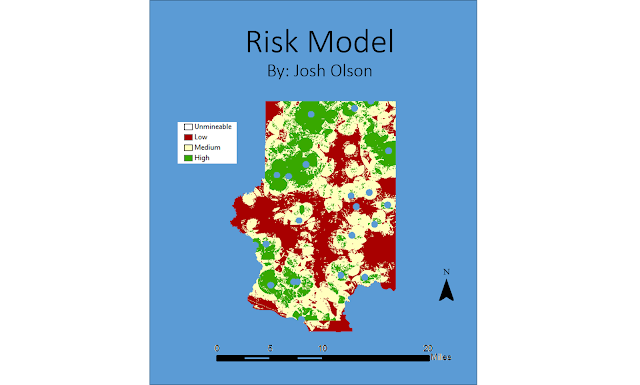

| Figure 15. Risk model created by summing the risk factor values. |

When all the risk factors are combined, it appears the area of lowest risk is a stretch across the central part of the county (Fig. 15). This creates potential issues, as it is a somewhat different recommendation than was presented by the suitability data.

|

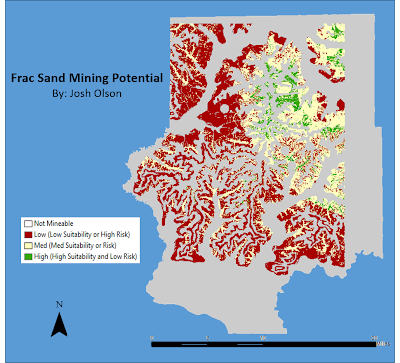

| Figure 16. Complete model that accounts for both suitability and risk in determining mining potential. |

When both models are combined into one complete model, a better understanding develops. The high suitability of the northeast corner is clearly shown, and the low risk section across the center of the county is largely masked by less than ideal suitability. The outside perimeter of the county appears to be the most likely region to not be mineable.

Conclusions

This exercise was valuable because it demonstrated the importance of looking at all the factors in a situation when drawing conclusions. Though each individual suitability/risk factor presented some bit of information, the big picture was rather unclear when looking at the mass of individual factors. However, by using geoprocessing tools and raster functionality, the individual factors were combined into useful information. In this case, the potential of the northeast portion of the county for mining is apparent. It would be interesting to see how the data would change if an additional rail location was added in the county, as it one of the more alterable factors in the model. Overall, the models demonstrate the potential of GIS to assist in decision making in a multi-million dollar industry.

Sources

WDNR -

ftp://dnrftp01.wi.gov/geodata/